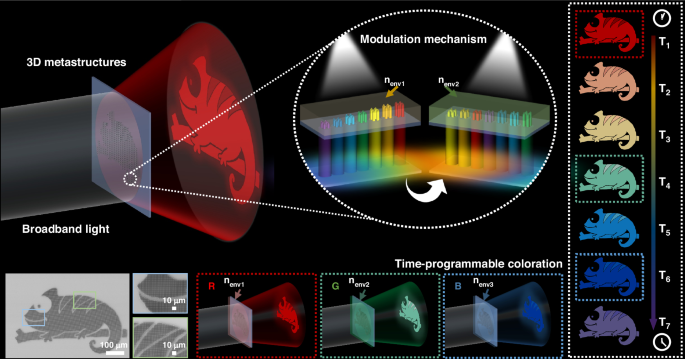

Modulation mechanism of time-programmable coloration

As illustrated in Fig. 1, when illuminated by broadband white light, the designed 3D metastructures allow only the light at the designed wavelength to be transmitted at a small angle and form a clear image in the far field, while other wavelengths are scattered at larger angles and thus suppressed, resulting in a monochromatic structural coloration effect. The wide-gamut coloration across the visible spectrum originates from the combined effects of Mie resonances and diffraction, with Mie resonances playing the dominant role and being strongly dependent on the geometric dimensions of the structures. Therefore, the coloration technology enabled by 3D metastructures requires precise design and fabrication of parameters such as diameter, period, and height of the structures34,35. Compared with traditional micro-nanofabrication techniques (such as ultraviolet lithography, electron/ion beam etching, and nanoimprinting), femtosecond laser 3D printing (FsL-3DP) based on two-photon polymerization (TPP) offers significant advantages. Owing to its nonlinear two-photon absorption characteristics and high energy threshold, FsL-3DP overcomes the planar limitations of conventional methods and enables subwavelength-scale fabrication resolution in 3D space, making it an ideal solution for realizing the designed 3D meta-devices36,37,38,39,40. As illustrated in Supplementary Fig. S1, a near-infrared FsL-3DP system was employed for the precise fabrication of patterned 3D metastructures (the dynamic fabrication process of the microstructures can be viewed in Supplementary Movie 1).

Under broadband white light illumination, the designed 3D metastructures precisely modulate the optical field to generate predefined colors and patterns in the far field. The enlarged inset illustrates the modulation mechanism of the structural colors produced by the 3D metastructures, where nenv1, nenv2 and nenv3 denote the environmental refractive indices corresponding to different device working environments. Morphological characterization of the chameleon-inspired patterned 3D metastructures is shown with scanning electron microscopy (SEM) images of the complete pattern and a magnified local region (bottom left). Time-programmable continuous color tuning achieved under varying environmental refractive indices is illustrated on the right, where T₁–T₇ represent the corresponding programmable time points. The bottom insets depict representative R/G/B output states under three distinct refractive index conditions

It is worth noting that the spectral and color presentation of the structural colors is usually inevitably influenced by factors such as the numerical aperture (NA) of the objective lens in the imaging system and the tilt angle of the sample. To evaluate the NA dependence, transmission spectra under different NA conditions were simulated (Supplementary Fig. S2). The results show that when the objective lens NA varies from 0.1 to 0.6, the main coloration wavelength of the structural patterns remains stable, with only minimal changes in the overall spectral shape. This conclusion is further supported by experimental results, where consistent structural coloration patterns were observed without significant color shifts when using objective lenses with different NA values (0.1–0.55) (Supplementary Fig. S3), in good agreement with the simulation. In addition, when the sample tilt angle deviates less than 15° from the normal direction, the main peak position of the transmission spectrum also remains largely unchanged (Supplementary Fig. S4). This excellent stability can be attributed to the weak angular dispersion characteristics of the designed metastructures, effectively reducing the system’s sensitivity to variations in the incident and collection angles.

Moreover, the coloration of 3D metastructures is not only determined by geometric parameters but also strongly dependent on the refractive index of the working environment. Building upon this foundation, dynamic modulation of the environmental refractive index enables time-programmable and continuously tunable coloration of the metastructure’s transmission spectra. By altering the refractive index contrast between the metastructures and the surrounding medium through external stimuli, the effective optical path length and phase distribution can be reconfigured, resulting in continuous yet programmable shifts of the transmission spectrum. This approach allows the structural colors to evolve along the time axis in a controlled and continuous manner. Simulation results (Supplementary Fig. S5) demonstrate that the transmission spectra of the same structure exhibit systematic shifts under different environmental refractive indices, confirming the feasibility of refractive-index-mediated time-programmable continuous coloration. This mechanism not only imparts time-programmable response characteristics with continuous tunability to structural color but also provides a new paradigm for information encryption and optical security, offering enhanced flexibility and robustness against potential attacks.

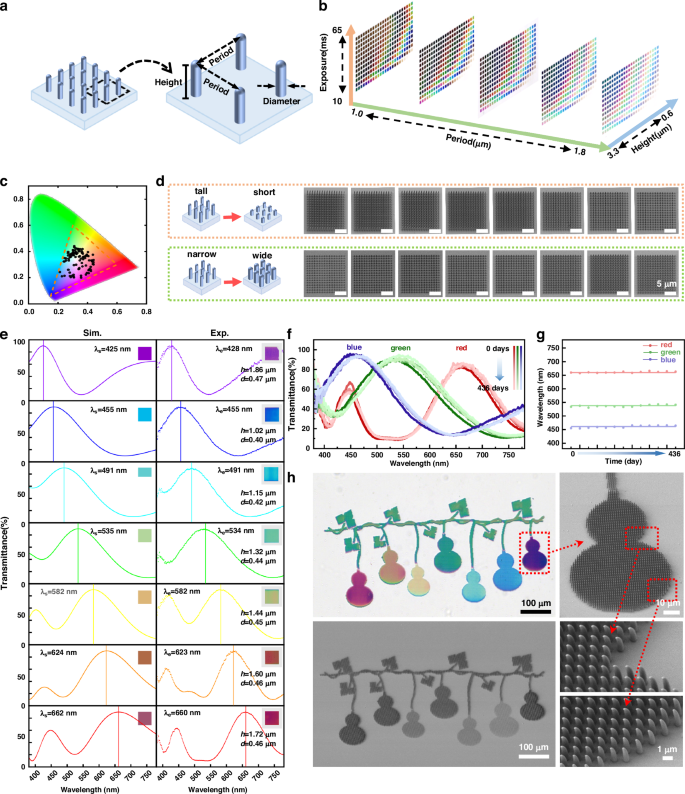

Performance evaluation of as-fabricated metastructure colors

The coloration properties of structural colors are closely correlated with the height, diameter, and period of the metastructures (Fig. 2a). To systematically investigate the influence of these parameters on color modulation, a large-area 3D structural color palette was designed and fabricated. The diameter of the metastructures was controlled by adjusting the point exposure time in the FsL-3DP process. During the fabrication of the palette, the exposure time was varied from 10 to 65 ms (in 5 ms increments), the structure height ranged from 0.6 to 3.3 μm (in 0.1 μm steps), and the period ranged from 1.0 to 1.8 μm (in 0.2 μm steps), with a constant writing power of 15 mW. Observations under transmission optical microscopy (Fig. 2b) reveal that the printed structural colors exhibit excellent color gamut coverage. Notably, the color brightness correlates with the structural period, whereas the dominant hue is primarily governed by the structural height and diameter, with a stronger dependence on height (Detailed simulation results are provided in Supplementary Fig. S6). Figure 2c presents the CIE 1931 chromaticity diagram of structural colors with a fixed period of 1.2 μm, indicating a wide color gamut and confirming the outstanding color-rendering performance of the system. Furthermore, scanning electron microscopy (SEM) images of the microstructures in the 1.2 μm period palette, featuring gradients in height (1.3–0.6 μm) and diameter (corresponding to exposure times from 65 to 35 ms), clearly demonstrate the precise 3D control capability of the FsL-3DP technique (Fig. 2d). Based on these results, rainbow colors printing was successfully achieved, and the transmission spectra of monochromatic structural arrays corresponding to seven different colors were simulated and experimentally measured (Fig. 2e), showing good agreement between simulations and experiments. These results verify that the structural color can be precisely designed and modulated. The images and spectra of the metastructures were collected using the system shown in Supplementary Fig. S7.

a Schematic illustration of the characteristic parameters of the metastructures. b 3D transmission palette of metastructures with varying heights, periods, and exposure times. c CIE 1931 chromaticity diagram of structural colors at a period of 1.2 μm. d Schematic diagrams (left) and SEM images (right) illustrating the control of height (top) and diameter (bottom) in 3D metastructures. e Simulated (left) and experimental (right) normalized transmission spectra of monochromatic metastructure arrays, with insets showing the corresponding perceived colors. All structures share a period of 1.2 μm, and the labels below each inset denote the structure height h and diameter d. f Long-term transmission spectra of RGB metastructures, where color depth (five levels) indicates the progression of time. g Long-term statistical analysis of the peak position variations of the transmission spectra shown in (f). h Full-color 3D-printed structural color patterns. Transmission optical microscopy image (upper left) and panoramic SEM image (lower left); complete SEM image of the purple gourd-shaped structure (upper right) and corresponding magnified SEM view (lower right)

Long-term stability and photostability are among the core metrics for evaluating the performance of color output devices. To systematically assess the long-term stability of structural colors, a stability tracking experiment spanning over 430 days was conducted. The evolution of the transmission spectra of RGB micro/nanostructures over the testing period (Fig. 2f), as well as the dynamic variations in the spectral peak positions (Fig. 2g), showed that the spectral curves at different time points exhibited high overlap, with fluctuations of the characteristic peak positions consistently controlled within ±5 nm, thereby fully confirming the excellent long-term stability of the structural colors. To evaluate photostability, a comparative photobleaching experiment between the structural colors and conventional dyes was designed. Under focused laser irradiation at 410 nm with a power of 8.54 mW for 3 h, both the structural color samples and Rhodamine B dye samples were tested. During the irradiation process, the fluorescence intensity of the traditional dyes decayed significantly, whereas the optical properties of the structural color samples remained stable (detailed comparative statistics are provided in Supplementary Fig. S8). This pronounced difference is attributed to the coloration mechanisms: unlike dyes, whose coloration relies on molecular structures, the physical coloration mechanism based on nanostructures effectively avoids photobleaching effects41,42. These results, evaluated from the perspectives of long-term stability and photostability, demonstrate that structural color technology exhibits superior durability compared to conventional dyes, offering unique advantages for applications requiring sustained color retention, such as anti-counterfeiting and information encryption.

In addition to a wide color gamut and excellent long-term stability and photostability, the practical application of structural colors also requires the capability to fabricate complex patterns. In this study, complex metastructured patterns were successfully printed by precisely programming the motion commands of the displacement stage and galvanometer in the FsL-3DP system. For monochromatic and multicolored patterns, a monochrome emblem of Jilin University and an RGB tricolor hot air balloon structure were successfully fabricated, respectively (Supplementary Fig. S9). To further demonstrate the capability of printing full-color complex patterns, Fig. 2h presents a structural color pattern featuring seven distinct colors, where the green design utilizes a higher structure than the rainbow one to obtain improved color saturation. The localized SEM images of the purple gourd-shaped structure in different regions reveal a uniform surface morphology, confirming the processing stability of the FsL-3DP technique. In summary, the 3D metastructure colors exhibit outstanding coloration performance, stability, and designability, demonstrating strong practical potential for applications requiring high security and durability, such as anti-counterfeiting labels, information storage, and encryption.

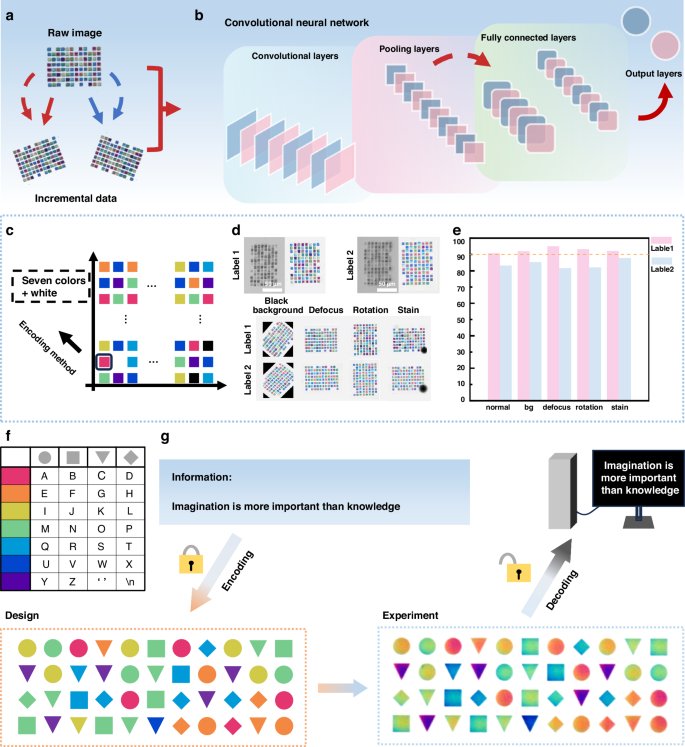

Structural color-based anti-counterfeiting labels and information storage

Leveraging the superior performance of structural colors in precise color modulation, long-term stability, and structural designability, their application potential in micro/nano-optical anti-counterfeiting and information storage has been further explored. For anti-counterfeiting purposes, two structural color anti-counterfeiting label templates were designed (Supplementary Fig. S10), and batch fabrication of structural color label arrays with submicron morphological uniformity was achieved using FsL-3DP technology (Supplementary Fig. S11). The fabricated labels exhibited high uniformity in both macroscopic morphology and coloration characteristics, demonstrating the excellent stability and reproducibility of the manufacturing process and providing a solid foundation for the practical deployment of large-scale anti-counterfeiting applications. To enable efficient and accurate recognition of the anti-counterfeiting labels, a convolutional neural network (CNN)-based recognition model tailored for structural color labels was developed. Considering the difficulty in constructing effective negative sample sets in real-world scenarios where counterfeit labels lack standardized formats, only positive samples (Label 1) were used to build the initial training dataset, thereby realistically simulating practical application conditions. To address the challenges of model training under limited sample conditions, image data augmentation strategies were employed, expanding the original dataset tenfold through geometric transformations such as image rotation and scaling (Fig. 3a), significantly enhancing the model’s adaptability and robustness to image features. Figure 3b shows the architecture of the constructed CNN model. In addition, Fig. 3c illustrates the coding scheme for the anti-counterfeiting labels, where each label consists of 8 × 12 color units, with each unit capable of displaying eight different colors (including rainbow colors and white). The spatial arrangement of different colors generates a vast number of possible combinations, endowing the coding structure with high information entropy and design flexibility, thus significantly enhancing the security and forgery resistance of the labels. To verify the practical anti-counterfeiting performance of the system, a testing set containing five scenarios (normal, black background, defocus, rotation, and stain) was constructed, as shown in Fig. 3d. Experimental results (Fig. 3e) show that when the confidence threshold was set to 90, the CNN achieved an accuracy of 99.4% over 530 recognition attempts, with true positive rate (TPR), false positive rate (FPR), true negative rate (TNR), and false negative rate (FNR) of 99.25%, 0%, 100%, and 0.75%, respectively. These results confirm the robustness of the structural color-based anti-counterfeiting system under complex environmental conditions. Benefiting from its submicron-scale resolution (Supplementary Fig. S12, minimum color unit <1 μm), the structural color anti-counterfeiting design offers high replication cost and difficulty, suitable for machine-fingerprint authentication of high-value devices.

a Schematic illustration of label data augmentation. b Schematic diagram of the convolutional neural network (CNN) architecture. c Schematic diagram of label encoding. d Transmission optical microscopy and SEM images of labels under normal conditions (top); transmission optical microscopy images of labels under different conditions (bottom), including black background, defocus, rotation, and stain. e Recognition results for unknown labels. f Schematic illustration of structural color information encoding rules. g Schematic diagram of encoding the designated information “Imagination is more important than knowledge” into a structural color matrix based on the encoding rules, along with the transmission optical microscopy image of the fabricated structural color matrix and its decoding illustration

In the field of information storage, the FsL-3DP technique was employed to fabricate microscale barcodes and QR codes for information encoding and retrieval within limited spaces (Supplementary Fig. S13), demonstrating the potential of structured patterns for high-density storage. Building upon this, a more scalable and readable structural color encoding system was further developed. As illustrated in Fig. 3f, by combining seven distinct structural colors with four distinct geometric configurations, an information mapping library containing 28 independent encoding units was established to represent English letters, spaces, and line breaks. To verify the application potential of this system in information storage, a conceptual demonstration was conducted by encoding the famous quote by Einstein, “Imagination is more important than knowledge.” A total of 44 characters were encoded into an 11 × 4 structural color matrix and fabricated as a microscale pattern using FsL-3DP (Fig. 3g), with a center-to-center spacing of 120 μm between encoding units, achieving an information density of up to 5.56 × 10⁸ bits/m². Furthermore, the encoded array can be accurately recognized and decoded using computer vision algorithms combined with decoding rules. The intrinsic stability of structural colors facilitates long-term information preservation. The effective information capacity of this storage scheme depends on the receiver’s minimum discernible color-difference threshold, fabrication accuracy, structural tolerance, minimum pixel size, and the dimensionality of the encoding. Notably, the minimum pixel in our scheme can be realized by a single nanopillar, which offers a higher upper bound on capacity. With further improvements in FsL-3DP fabrication resolution and expansions in the encoding dimensions—such as incorporating richer structural color features or multilayer encoding strategies—the information carrying capacity per unit area of the system can be significantly enhanced, providing a novel pathway toward the development of next-generation high-density, visual, and sustainable information storage technologies.

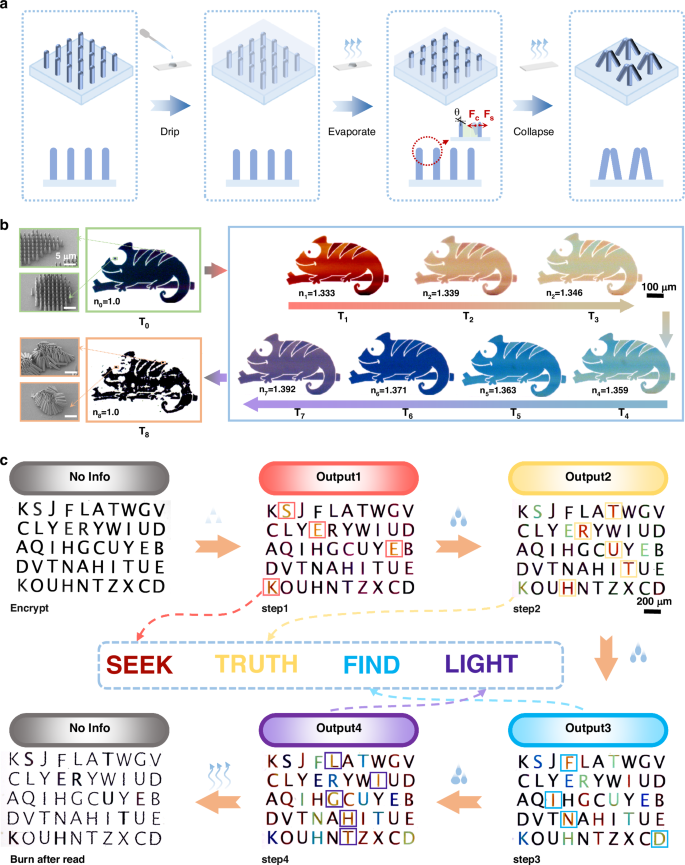

Time-programmable structural colors for optical information encryption

The spectral response of the metastructures is highly sensitive to the refractive index of the surrounding medium, thereby enabling time-programmable and continuously tunable coloration through refractive index modulation. Liquid tuning, which offers advantages such as cleanliness, low cost, and environmental friendliness, serves as an effective approach for refractive index modulation43,44. Specifically, by introducing liquids with tailored refractive indices, the refractive index contrast between the nanostructures and their environment can be adjusted, providing precise control over the resulting structural coloration. Moreover, beyond spectral tunability, the infiltration of liquids also induces a mechanical response at the structural level, further enriching the multi-physics functionality of the system. During the evaporation process, the metastructures are subjected to a competing interplay between lateral capillary forces (\({F}_{C}\)) and structural support forces (\({F}_{S}\)) (Supplementary Fig. S14), which can be respectively expressed as45,46,47,48

$${F}_{C}\approx \frac{\gamma {hw}\cos \theta }{d}$$

(1)

$${F}_{S}\approx E\frac{{w}^{4}d}{{h}^{3}}$$

(2)

Among them, \(\gamma \) denotes the surface tension between the liquid and the structure, \(h\) and \(w\) represent the height and diameter of the metastructures, respectively, \(\theta \) is the contact angle between the liquid and the metastructures, \(d\) is the period of the structures, and \(E\) is the Young’s modulus of the structural material. As indicated by Eqs. (1) and (2), to enable automatic collapse of the structures during liquid evaporation and thereby accomplish secure information destruction, the metastructures must possess appropriate height and diameter, together with a relatively small period, so that the deformation threshold can be reached under capillary forces. However, if the designed height is excessively large or if the diameter and period are too small, the mechanical stability of the structures would be significantly reduced, making them vulnerable to unintended damage from liquid flow or diffusion, which could cause premature collapse or unwanted color distortion. Therefore, to simultaneously ensure reliable time-programmable coloration and irreversible collapse during the evaporation stage, the geometric parameters of the metastructures must be carefully optimized to balance optical performance with mechanical response (a detailed schematic is provided in Fig. 4a). This self-destructive mechanism operates without external energy input, featuring low energy consumption and environmental friendliness, thereby offering an efficient and sustainable pathway for green, secure information encryption and destruction.

a Schematic illustration of the self-erasing process. b Optical microscopy images showing the time-programmable coloration and self-destruction process of the chameleon pattern at different time points (T₀–T₈). T₀ represents the initial state in air; T₁–T₇ correspond to the sequential programmable color transition from red to purple; T₈ denotes the final state after structural collapse. n0–n8 denote the environmental refractive indices of the structure at the corresponding time points. Insets on the left show the corresponding SEM images at T₀ and T₈. c Transmission optical microscopy images of time-programmable encrypted information at different decryption steps, including the initial state, decryption results of the first to fourth layers (Output1-4), and the final state after structural self-destruction

Figure 4b illustrates the time-programmable coloration and self-destruction process of a chameleon pattern constructed based on this mechanism. In air, the pattern appears black, with SEM characterization confirming the orderly arrangement of the structures. Upon the introduction of deionized water (n = 1.33), the pattern instantly turns red. Subsequently, by gradually increasing the concentration of glycerol (n = 1.475) to create a continuous refractive index gradient, sequential and programmable modulation of the structural coloration is achieved. As time progresses, the pattern color transitions in a continuous and controllable manner from orange (n = 1.339), yellow (n = 1.346), green (n = 1.359), cyan (n = 1.363), and blue (n = 1.371) to purple (n = 1.392), thus realizing a full-spectrum programmable transition from red to purple across the entire visible range (as shown in Supplementary Movie 2). It is evident that an average change in refractive index of 0.010 already produces a discernible color difference, and a change of 0.059 yields a full transition from red to purple, indicating that the spectral response of the metastructures is highly sensitive to the refractive index of the surrounding medium. Finally, with the evaporation of the liquid, the pattern color disappears and the structures collapse. Transmission optical microscopy and SEM imaging confirm that the metastructures undergo irreversible deformation under capillary forces, thereby completing the secure self-destruction of the information.

The aforementioned time-programmable and continuously tunable coloration capability enables information to be dynamically encoded within a single physical structure, while the self-destruction mechanism provides a secure “burn after reading” functionality. Thus, this time-programmable structural coloration strategy offers an ideal pathway for constructing high-security optical information encryption systems. As a proof of concept, an encrypted structure containing four pieces of encoded information was designed (the geometric parameters design and detailed theoretical analysis are provided in Supplementary Fig. S15). Figure 4c presents the complete decryption and self-destruction process. In the initial state, a random array of letters appears uniformly black, and the encrypted information cannot be distinguished using transmission/reflection optical microscopy, dark-field microscopy, fluorescence microscopy, or SEM (Supplementary Fig. S16). Upon the introduction of deionized water, the first encrypted message, “SEEK,” immediately appears due to the change in environmental refractive index. Subsequently, as a refractive index gradient is established by the diffusion of glycerol, the following messages “TRUTH,” “FIND,” and “LIGHT” sequentially emerge, realizing a time-programmable decryption process (Supplementary Movie 3). Notably, the initial response is nearly synchronous with liquid coverage, whereas the emergence speed of subsequent messages is dictated by the diffusion rate of glycerol in water. Under current experimental conditions, the full decryption process takes ~125 s, but the response time could theoretically be reduced to the millisecond scale by employing liquids with faster diffusion rates. After all information is revealed, the system naturally enters the collapse phase during liquid evaporation, where capillary forces induce irreversible deformation of the nanostructures, achieving automatic and secure information erasure. Follow-up tests confirmed that even after liquid reintroduction, no color change or patterns reappeared, unequivocally demonstrating the one-time readability and complete destruction of the system (detailed in Supplementary Movie 4). Although only four messages are demonstrated here, the encoding capacity can be further expanded in practice, with the upper limit primarily determined by the receiver’s ability to discriminate color differences. Furthermore, introducing a combined transmission–reflection channel within the same device49,50, or superimposing orthogonal degrees of freedom such as polarization and incidence angle51,52, can significantly enhance the effective information capacity without increasing spatial multiplexing. This study therefore establishes a time-programmable coloration encryption strategy integrating programmable encoding, sequential decryption, and secure self-destruction, providing a novel pathway toward next-generation high-security optical encryption technologies.